HVAC Valve Troubleshooting

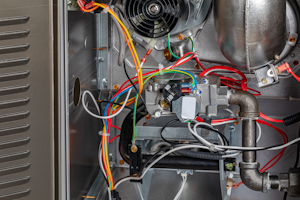

Figure 1: HVAC valve troubleshooting can be complex, so it's important to know the basics.

Troubleshooting valves in an HVAC system is critical for ensuring the system operates efficiently and reliably. Valves play a pivotal role in regulating the flow and pressure of air and fluids within these systems, and any malfunction can lead to compromised performance, increased energy consumption, or even system failure. By understanding how to diagnose and rectify common valve issues, technicians can prevent costly downtime, extend the lifespan of the HVAC system, and maintain optimal comfort levels in residential or commercial buildings.

Valves in HVAC systems

The following valves are commonly found in HVAC systems. Learn more about HVAC valve types in our HVAC valves overview article.

- Solenoid valves

- Butterfly valves

- Globe valves

- Ball valves

- Check valves

- Gate valves

- Zone valves

- Pressure relief valves

View our online selection of valves commonly used in HVAC systems!

HVAC valve issue symptoms

Identifying faulty HVAC valve symptoms early can prevent more significant issues and ensure the longevity of the HVAC system. Below are common symptoms that may indicate a problem with an HVAC valve:

-

Inconsistent temperature regulation

- Rooms do not reach the set temperature

- Temperatures fluctuate or there are hot and cold spots within a space

-

Unusual noises

- Hissing sounds may suggest a refrigerant leak

- Whistling or chattering noises may indicate improper valve seating or operation

-

Reduced airflow

- Weak airflow from vents, meaning the system cannot circulate air efficiently

-

Increased energy consumption

- Sudden spikes in energy bills because the system requires more energy to maintain desired temperatures

-

System short cycling

- The HVAC unit turns on and off frequently

- The HVAC unit fails to complete a full heating or cooling cycle

-

Leakage around valves

- Visible signs of moisture or refrigerant near valve fittings

- Accumulation of ice or frost on valves or piping

-

Pressure irregularities

- Abnormal pressure readings in the system

- The system cannot maintain stable pressure levels

-

Inability to start

- The HVAC system fails to initiate heating or cooling cycles

- The system does not respond to thermostat adjustments

Troubleshooting common HVAC valve issues

This section overviews the symptoms discussed in the previous section and how to troubleshoot valves to determine if they are the cause of the symptoms and the potential fixes.. The next section offers helpful resources on the recommended fixes.

Faulty actuator or miscalibrated valve

A faulty actuator or miscalibrated valve can lead to rooms not reaching the set temperature, temperature fluctuations, and hot and cold spots within a space.

-

Troubleshooting

- Ensure the valve actuator operates correctly and responds to control signals.

- Check that the valve is properly calibrated to match the control system's requirements.

-

Fixes

- If the valve is stuck, unresponsive, or not fully opening and closing, it may need cleaning, lubrication, recalibration, or even replacement.

- If the valve is operating as expected but problems continue, further investigation into other system components like the thermostat and control board is necessary.

Faulty connections or improper valve seating

Faulty connections, either loose or damaged, and improper valve seating can lead to unusual noises, such as hissing or whistling, during operation.

-

Troubleshooting

- Inspect valve connections for tightness and signs of damage.

- Listen to the valve during operation to determine if the noise corresponds with specific movements or positions, which can help isolate the issue.

-

Fixes

- Tighten loose connections that do not show any signs of damage. If possible, check with the valve manufacturer's product sheets to determine maximum connection tightness. Overtightening can damage the connection.

- If necessary, disassemble the valve to determine if the closing element or valve seat is damaged, which may be leading to improper valve seating.

Valve not opening or closing fully

Several issues can occur if a valve does not open or close fully. For example, a valve that does not open fully can lead to reduced airflow in a system. This causes the system to work harder to attempt to maintain set parameters. Alternatively, a valve that does not close fully can lead to leakage and increased energy consumption. All of these issues can cause sudden spikes in energy bills.

-

Troubleshooting

- Examine the valve for any blockages or debris that may prevent full opening or closing.

-

Fixes

- Disassemble the valve to determine if any debris is blocking the sealing mechanism from opening or closing fully.

- Ensure the actuator receives the correct signal and has the power and torque necessary to operate the valve.

Improperly sized valve

Improperly sized valves can cause similar problems to valves that do not open or close properly.

-

Troubleshooting

- Determine if the HVAC system is short cycling, meaning frequent on and off cycling.

-

Fixes

- Investigate the valve's size and the system's requirements. Learn more about how to size a valve in our Kv calculator and Cv calculator articles.

Leakage

Valve leakage can lead to several of the above HVAC symptoms:

- Reduced airflow

- A valve that is working a lot to maintain set parameters

- Energy bill spikes

Furthermore, leakage of refrigerant can be dangerous. Therefore, troubleshooting a valve for leakage is an essential component of HVAC valve troubleshooting.

-

Troubleshooting

- Investigate valves and their fittings for signs of moisture or refrigerant or accumulation of ice or frost on valves or piping.

-

Fixes

- Inspect valve seals and connections for integrity. Replace worn seals.

- Tighten or replace fittings as necessary, and consider replacing the valve if it shows signs of wear or damage.

Pressure irregularities

Abnormal pressure readings in the system, or an inability to maintain stable pressure levels, can be traced back to valve issues.

-

Troubleshooting

- Use a pressure gauge to monitor the system's pressure at various points, including before and after the valve.

-

Fixes

- If the valve appears to be the source of the problem, determine whether it is opening fully or if there is a blockage in the valve.

HVAC system does not start

If the HVAC system fails to initiate heating or cooling cycles, or does not respond to thermostat adjustments, the issue may lie with the valves.

-

Troubleshooting

- Ensure that the valves are receiving power and control signals.

- Check for any mechanical obstructions or electrical faults that could prevent valve operation.

-

Fixes

- If the valve appears to be the source of the problem, further diagnostic testing or replacement may be necessary.

Resources for fixing HVAC valve issues

There are several different approaches to fixing an issue with an HVAC valve. This section offers resources available in our Technical Information Center. It is not an exhaustive list; check out our Installation and Troubleshooting section to learn more about troubleshooting and repairing specific valve types.

- Lubrication: Improper lubrication can lead to wear of mechanical components in a valve. Read our guide on lubricant types, uses, and functions to learn more.

- Cleaning: Cleaning a valve can return it to proper functioning. Learn more about this topic in our CIP and SIP overview article and our guide on how to clean a solenoid valve.

- Valve replacement: In extreme cases, complete valve replacement may be necessary to return the HVAC system to normal function. We have several articles on this topic, such as our article on how to replace a ball valve.

- Seal replacement: Replacing a seal can be the solution to valve leakage. O-rings are a common valve seal. Read our article on how to replace, measure, and install o-rings.