Hydraulic Jacks - Maintenance And Repair

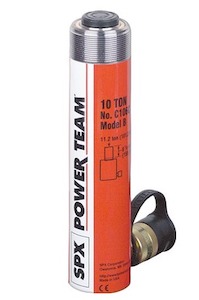

Figure 1: Hydraulic jack

Hydraulic jacks operate using pressurized hydraulic fluids to lift heavy objects. They are tough devices but can sustain damage from continuous use, environmental elements, or improper maintenance, all of which compromise their ability to perform well. This article discusses hydraulic jack maintenance, common problems, and their solutions.

Table of contents

View our online selection of hydraulic jacks!

Hydraulic jack problems and solutions

Hydraulic jacks are mechanical devices that lift heavy loads over long distances. They are popular in the construction and automotive industries. There are six primary components of a hydraulic jack:

- Reservoir: Stores the hydraulic fluid for a change in pressure.

- Pump: Pushes the hydraulic fluid from the reservoir through a check valve to the main cylinder.

- Check valve : Prevents the return of fluid to the lever from the cylinder and maintains pressure at the load.

- Main cylinder: Transfers the pressure of the hydraulic fluid.

- Ram piston: Lifts the load.

- Release valve: Returns pressurized fluid to the reservoir.

Regular maintenance is necessary for hydraulic jacks to troubleshoot issues immediately whenever they come up. A hydraulic jack system exhibits different symptoms depending on the issue, which helps users identify the problem. Common hydraulic jack problems and their solutions are discussed in the next section.

Hydraulic jack unable to lift the weight

A hydraulic jack fails to lift heavy loads if its ram is not working properly. This happens for multiple reasons like rust, lack of lubrication, overloading, or low/high oil level in the reservoir. There are a few solutions to this issue.

- Every hydraulic jack has a specified lifting capacity. Before choosing a hydraulic jack, check its specifications in its manual to avoid overloading.

- Tighten the caps and replace worn seals to prevent the entry of air and other foreign particles. Air and other trapped particles inhibit the proper transmission of pressure from the hydraulic fluid to the load.

- Improve the jack’s lifting ability by using a lubricant on the moving parts.

- Periodically inspect the hydraulic fluid level and maintain an optimum level to overcome issues related to insufficient/excess fluid levels.

- Rust between metal parts causes the jack to leak or hinder the movement of components due to friction. Remove the rust from the affected areas or replace the parts if necessary.

Hydraulic oil leakage

Hydraulic oil can leak internally and externally due to damaged seals/o-rings or inappropriate fittings. Corroded metal parts also cause hydraulic fluid leaks. Visually inspect the device for any external leaks. If necessary, replace the damaged seals/o-rings and the fittings by ordering a hydraulic jack rebuild kit. The tank can also overflow, so remove excess oil from the tank in this case.

Restricted jack wheel movement

Smoothly rolling jack wheels is essential to moving the hydraulic jack from one place to another. If the jack wheel doesn’t move properly, it may be difficult for the operator to perform multiple tasks. Corrosion of parts and lack of lubrication are the common reasons for restricted jack wheel movement. Use a lubricating oil to reduce friction and ensure smooth operation of the wheels. Store the hydraulic jacks in dry places to prevent moisture buildup and rust within the internal parts.

Lever failing to raise

Often, the jack’s lifting lever fails to raise under the weight of the load. This happens when the valves are not closed properly or there is foreign material in the valves. In this case, clean the valves by performing the following steps:

- Lower the jack’s piston rod

- Close the vent valve

- Raise the jack’s piston rod manually

- Open the vent valve and lower the piston rod quickly

Jack fails to lift to the maximum height

Air bubbles in the hydraulic circuit obstruct the jack from lifting to its maximum capacity. Purge air in the hydraulic circuit, as discussed in the next section.

Maintenance

Hydraulic jack maintenance is essential for an extended service of the tool and occupational safety. This section covers the standard practices to ensure proper maintenance of hydraulic jacks. Refer to the manufacturer’s manual for the frequency required (daily/weekly/monthly) to perform these actions.

- Visual inspection: Check the general condition of the machine and look for damaged or missing parts.

- Leaks: Verify there is no measurable accidental loss in the hydraulic circuit. Slight moisture content is fine but should not be enough to form a drop.

- Cleaning: Clean the device to free the external structure and moving parts from accumulating dirt and dust. For this, empty the hydraulic fluid, flush it, and blow out the system. Use proper equipment and solvents for cleaning the device.

- Lubrication: Grease the moving parts of the hydraulic jacks, like the lever, wheels, adjustment screws, and hinges.

- Oil level: Check the oil level in the tank and top up with hydraulic mineral oil if necessary. Use only the oil type recommended by the manufacturer. Never use brake fluids or engine oils, as they can degrade the seals.

- Storage: Release the pressure from the device and keep it in its intended position as suggested by the manufacturer to avoid air bubbles in the hydraulic system.

-

Bleed air from the hydraulic circuit: Trapped air bubbles reduce the efficiency of a hydraulic jack. Perform the following steps to remove trapped air from the device:

- Open the vent valve by turning it counterclockwise. Also, open the oil tank cap.

- Pump repeatedly to release the air.

- Close the vent valve by turning it clockwise. Replace the oil tank cap by applying pressure on it.

- Check if the jack functions properly.

Read our hydraulic bottle and floor jack articles for more information on the working of each jack type. Learn more about these tools by reading our hydraulic jack overview article.

FAQs

Can I use brake fluid in a hydraulic jack?

No. Using brake fluids or engine oils can degrade the seals. Use only the oil type recommended by the manufacturer.

What is a substitute for hydraulic jack oil?

Use machine oil, ATF (automatic transmission fluid), or lightweight motor oil with viscosity grades 10W or 20W as substitutes for hydraulic jack oil.

How to put hydraulic fluid in a floor jack?

To refill a hydraulic jack, first, level the jack on the ground. Open the release valve to access the filler plug. Remove the plug and fill the reservoir with oil. Replace the filler plug when done.

Why does my hydraulic jack not go all the way up?

Air trapped within a hydraulic pump can cause the jack to remain stuck in the up or down position. In this case, purge (bleed) the air from the jack.