What is Water Hammer?

Figure 1: The effects of water hammer can burst pipes.

Water hammer, technically called a hydraulic shock, is a piping phenomenon that occurs when a fluid in motion is forced to stop or change direction suddenly. It occurs mainly with liquids, like water, due to incompressibility, but it can also occur in gasses. The sudden change in fluid momentum, typically by a closing valve, causes a pressure surge that sends a wave at the speed of sound back and forth in the piping network.

The effect of water hammer is associated with a banging sound that may be repeated a few times before the pressure dissipates. The pressure surge can be several times the operating pressure limit of the piping system leading to potential damage of the pipe, the equipment attached to the pipe, and in some cases, it can pose a danger to people and the environment. It is more prominent for electric or pneumatic valves that shut fast, like a solenoid valve.

Causes of water hammer

As explained, water hammer occurs in a piping system when fluid runs into a wall, and the force causes a pressure surge in the piping network. The most common wall is when a valve quickly closes. Looking at a few common applications, we can see how water hammer is caused in them:

Residential application

In a residential application, when a dishwasher or washing machine turns off the water, a solenoid valve closes quickly and may cause water hammer effect. Typically, it doesn't cause damage, but you can hear it.

Industrial processes

Similar operations in industrial processes like quickly closing a valve downstream of a running pump can lead to water hammer. Other industrial processes include:

- A sudden stop of a tight seal pump: When a column of water is moving through a pump (a positive displacement pump, and not a rotodynamic pump), a sudden stop of the pump without gradually slowing down will cause water hammer. In this case, the pump acts as a downstream valve that is suddenly closed.

- Slam shut of a check valve: Water hammer can occur when a check valve closes. Check valves can close almost instantaneously if the pressure differential is below the check valve’s specifications.

- In steam production: In steam production start-up of operation, the high rate of condensation leads to a slug of liquid condensate traveling at a high velocity. When this liquid hits a sharp bend, the phenomenon of water hammer is experienced.

- Upstream of a running pump: A reverse effect happens when a valve upstream of a running pump is suddenly closed, resulting in a vacuum just after the valve. This vacuum can lead to the implosion of the pipe.

- Initial pipe filling: A different occurrence of water hammer happens when filling an empty pipe with water at high rates and the air is released through a small hole. When the air is completely out of the pipe, water flow is suddenly stopped, leading to a pressure surge.

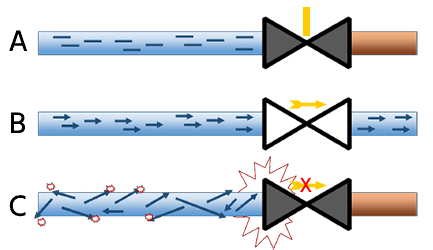

Figure 2: The water hammer effect: the initial condition with closed valve and standing water (A), normal operation with open valve and water flow (B), water hammer with suddenly closed valve (C). Water momentum is converted to pressure waves moving back and forth within the pipe.

Effects of water hammer

The most basic result of water hammer is the banging noise and the vibrations when the wave bounces back and forth in a pipe network. The vibrations can lead to weakened pipe joints and connections, deformed pipes, and weakened supports and hangers. It can also lead to leakages, pipe damage, and damage to the equipment (instruments, pumps, or pressure gauges) attached to the pipe. In rare but severe cases, it can lead to accidents and sometimes fatalities.

How to prevent water hammer

Figure 3: A Brass Angle Seat Valve EPDM 10 bar Drinking Water. There is no risk of water hammer in this valve due to its slow-closing mechanism.

During pipe network design and construction, it is vital to assess water hammer risk in the pipe system and install preventive measures. You should carefully consider the fluid flow control. Possible measures to mitigate against water hammer are:

- Avoid fast closing valves: Manual valves should be closed slowly, especially when the pumps are still running. Fast closing solenoid valves should be avoided when other mitigating measures are not installed. For domestic purposes, angle seat valves or manual ball valves that you close slowly are an excellent valve to use in drinking water systems.

- Install expansion tanks, water towers, surge tanks, or hydraulic accumulators: These systems capture pressure surges by allowing expansion of the fluid and prevent water hammer.

- Reduce operating pressure: Quite often the main supply pressure is not needed across the pipe network. Throttling down the pressure locally will help prevent water hammer.

- Install pipes with high-pressure ratings: This does not prevent water hammering but protects against damaging the pipe

- Process operating procedure: Start-up and shutdown procedures should consider the effects of water hammer.

- Install blow-off valves and air valves: Air valves help to reduce low-pressure regions which prevent the acceleration of the fluid. Blow-off valves allow discharge of excess pressure in the flow.

Applications of the water hammer effect

The effects of water hammer generally have undesirable consequences, but it can have some useful applications when deliberately simulated. A hydraulic ram uses the water hammer effect to pump water by converting a water pressure head at a high flow rate to a higher pressure head at a low flow rate. The water hammer effect can also detect leakages in a pipe and detect enclosed air pockets.

Conclusion

Water hammer can be quite damaging to pipes and the equipment attached. The noise, vibrations, and pressure surge created can disturb people's comfort and lead to accidents. It is caused by the sudden stoppage of a fast-moving fluid, like water, typically by a valve or a sharp pipe bend. Several measures prevent water hammer, such as lowering operating pressure, slow-closing valves, and expansion tanks. The principle of water hammer can also have practical applications, such as pumping water, as seen with the hydraulic ram.