Burkert 6223 Proportional Solenoid Valve - How They Work

Figure 1: Burkert type 6223

The Burkert type 6223 is a 2/2-way, indirect operated proportional solenoid valve designed for continuous control of high flow rate fluids, requiring minimal differential pressure. It uses a servo-assisted plunger for effective opening and closing, featuring low hysteresis and high response sensitivity with pulse width modulation (PWM) control. While DC voltage can be used, PWM is preferred for precise and repeatable control. The rest of the article focuses on PWM control for this valve.

The Burkert 6223 is designed to be operated with a PWM controller, like the Burkert type 8605 or 8611. The valve provides easy integration with other Burkert products that satisfy mounting and configuration requirements thus, decreasing installation time and optimizing performance. Additionally, the valve is well protected from the environment with a brass or stainless-steel body and IP65 rating. This article discusses only PWM control of the Burkert 6223.

Buy Burkert 6223 Online Now!

Table of contents

- Is the Burkert 6223 the right valve for you?

- Operating principle

- Features

- What other products can it be used with?

- Applications

Is the Burkert 6223 the right valve for you?

This valve might be the right valve for your application if:

- Your medium is a liquid which requires large flow rates.

- Your system has a pressure differential of 0.5 bar (8 psi) or higher.

- A nominal orifice diameter between 13 and 20 mm is desired.

- Your maximum operating pressure is below 10 bars.

- Your system requires high response sensitivity for accurate positioning.

- Your system includes a PWM controller.

- Your system requires a tight closing valve.

Operating principle

The Burkert type 6223 is an indirect operated solenoid valve with the plunger directly coupled to a servo piston. It requires a minimum pressure differential (at least 0.5 bar) to open and close the valve. The plunger position is proportionally controlled with a PWM signal applied to the valve coil. The duty cycle of the PWM signal affects the position of the plunger. At 100% duty cycle, the plunger moves all the way upward and the valve is fully opened. As the percent range for the duty cycle changes between 0 to 100, so will the position of the plunger thus controlling the flow of the valve.

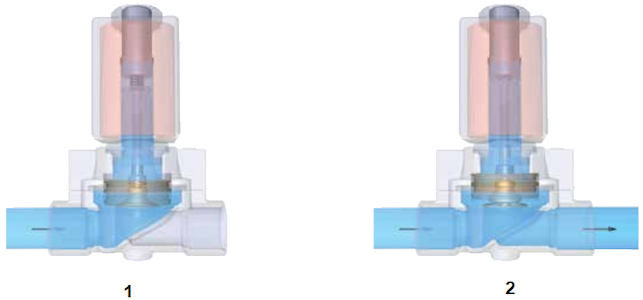

The opening and closing of the valve is assisted with the medium pressure as it flows in and out of a chamber through a pilot channel. During valve opening (Figure 2.2), as the pilot valve is activated, the chamber above the piston empties causing the pressure beneath the piston to rise and push open the valve. When the valve is closed (Figure 2.1), the medium flows through the pilot channel to the chamber above the piston causing the pressure to fully close the valve. A benefit of using a servo-assisted valve design is it requires a less powerful magnetic force to open the valve, which reduces power consumption and coil temperature over time. Although it should be kept in mind that a small differential pressure is required to move the piston. Additionally, the pilot channel must not be obstructed. Therefore, servo assisted valves are ideal for clean fluids and should have no particles in the fluid to block the channel hole.

The PWM signal applied to the valve coil is controlled using a controller, which is sold separately. The Burkert Type 6223 proportional valve uses a 24VDC operating voltage and is rated for continuous operation with a 100% continuous duty cycle.

Figure 2: Valve operation: closed valve (1) and open valve (2)

Features

Approvals for the 6223 valve

This valve series is available with the following ratings and approvals:

- IP65: With plug-on module or with cable plug on the valve.

- ATEX, IECEx: Approval of devices and protective systems used in explosion-prone areas.

Body and seal material

The materials available for this valve are optimal for neutral liquids such as water. The body material options are brass or stainless steel. The standard seal material is fluorocarbon rubber (FKM). FKM is resistant to oil and chemicals, and can operate in wide temperature range of -26°C to +230°C.

Port size range

The Burkert valve 6223 is available with port sizes from G 3/8“ to G 1“. The supported pressure range is from 0.5 bar to 10 bar. It is important to remember that a minimum pressure is required to fully open this valve. The table below shows the corresponding orifice sizes and Kv-value. The Kv value in the table indicates the flow rate of water in m3 per hour for water measured at 20 °C and 1 bar pressure differential over a fully opened valve. Correct valve sizing is very important to guarantee good performance of your system and to optimize costs. As a rule of thumb, select a valve with a Kv value that is slightly larger (ideally 10%) than the application. Use our valve sizing calculator to quickly determine the right valve size.

Table 1: Burkert 6223 proportional solenoid valve orifice sizes and Kv values

| Port size (BSP) | Orifice (mm) | Kv (m3/h) | Pressure (bar) |

| G 3/8” | 10 | 1.5 | 0.5-10 |

| G 1/2" | 10 | 1.5 | 0.5-10 |

| G 1/2" | 13 | 2.5 | 0.5-10 |

| G 3/4" | 13 | 2.5 | 0.5-10 |

| G 3/4" | 20 | 5.0 | 0.5-10 |

| G 1" | 20 | 5.0 | 0.5-10 |

What other products can it be used with?

The Bukert Type 6223 is delivered without control electronics or cable plug accessories. However, Burkert offers products designed specifically for the 6223 solenoid valve. By using a Burkert cable plug or controller, it will decrease installation time and optimize performance, however, they can be used in conjunction with non-Burkert products.

Cable plug type 2518

Burkert type 2518 as seen in Figure 3, is a cable plug according to DIN EN 175301-803 Form A for power connections. The Type 2518 is offered with a wide range of protection circuits and LED circuitry for fast installation and electrical component protection. The Type 2518 can be ordered in various voltages and frequency ranges. Ensure the proper model is selected for your valve.

Figure 3: Burkert Type 2518

Type 8605 controller

The Burkert type 8605 (Figure 4) is a PWM controller that can be used to optimize control of the Type 6223 valve. The 8605 can mount directly to the 6223 by using the DIN EN 175301-803 Form A (DIN-A) connection, giving them faster assembly and reduced integration time. The 8605 is equipped with valve operating points to optimize control and accuracy of the valve. The 8605 is an open-loop PWM controller without automatic error monitoring and correction. Applications which are stable and do not deviate from set point operating conditions are suitable for this controller.

Figure 4: Burkert Type 8605 Controller

Type 8611 controller

The Burkert type 8611 (Figure 5) is a multipurpose controller with PWM control capabilities. Similar to the 8605, the 8611 decreases installation time by using parameter-based configuration of valve operating points. Additionally, the 8611 includes a variety of inputs which can be used for sensor input to monitor process error. The 8611 uses a PI (proportional integral) control algorithm to monitor and reduce error over time. Applications which are unstable or require tight operating tolerances are well suited for the 8611 controllers. The 8611 can mount directly to the 6223 by using the DIN EN 175301-803 Form A (DIN-A) connection. The DIN-A connection connects the transistor output to the control valve, eliminating the need for extra wires or connection.

Figure 5: Burkert Type 8611 Controller

Applications

- Water dosing: Water dosing systems are used in various industries from agriculture, water treatment to manufacturing processes. Dosing systems are designed to deliver a precise flow of a fluid such as water into a pipe or tank being dosed. The Burkert Type 6223 is a good fit to be used in such applications. With a brass or stainless-steel body and IP 65 rating the 6223 is suitable to handle water. PWM control allows the 6223 to be controlled with low hysteresis, high repeatability, and high responsiveness. Additionally, the 6223 can operate at high flow rates and tightly close with its servo-assisted operation.

- Water cooling system: Water cooling systems are often used in water treatment plants to maintain water temperatures to limit growth of algae and cool equipment. Efficient operation of a water-cooling system requires precise control and high flow rates. The Burkert Type 6223 provides a water-cooling system with highly accurate control and can sustain high flow rates. Additionally, it can be accurately controlled in a closed loop system with a PWM Burkert controller such as the Type 8611.