Pneumatic Cylinder Rod-End Accessories

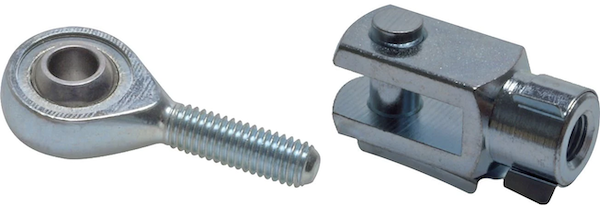

Figure 1: A rod-end spherical eye (left) and rod-end clevis for pneumatic cylinders.

Rod-end accessories connect a pneumatic cylinder to the load that it pushes or pulls. Choosing between them largely depends on the load's connection point and whether or not misalignment between the load and cylinder needs to be accounted for. This article takes a closer look at the most common rod-end accessories. To learn more about how pneumatic cylinders operate, read our pneumatic cylinder overview article.

Pneumatics glossaryView our online selection of pneumatic cylinders

Rod threads

Pneumatic cylinder piston rods typically have external or internal threads that allow the mounting of accessories such as a clevis or spherical eye. Threads come in various standards, including metric, NPT, and BSP. Read our thread compatibility article to ensure the accessory can connect to the piston rod.

Rod-end accessories

Three accessories are often used in connecting a load to a pneumatic cylinder's rod: spherical eye, clevis, and floating joint. This section looks further at each.

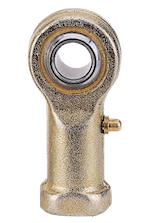

Rod-end spherical eye

ISO 8139 defines the mounting dimensions of a rod-end spherical eye for pneumatic cylinders, which is used to attach loads to the rod. Rod-end spherical eyes (Figure 2) are also called rod-end eyes and use female threads to attach to a male-threaded piston rod. A pin and clamp (or clevis) couple a load to the rod-end eye. Rod-end spherical eyes can compensate for misalignment issues by tilting with cylinder motion.

Application

Rod-end eyes suit linear (push or pull) and non-linear load travel. Using a rod-end eye, the cylinder body can rotate while the piston rod applies force to the load. If the force is not applied along the centerline of the cylinder due to misalignment, unwanted forces on the piston rod and bearings can occur.

Figure 2: A rod-end spherical eye

Rod-end clevis

Rod-end clevis attachments are also commonly called rod-end forks and can be seen in Figure 3. Rod end forks use female threads to attach to a male-threaded piston rod. A load is coupled to the clevis attachment with a pivot pin. ISO 8140 defines the mounting dimensions of rod-end clevises for pneumatic cylinders.

Application

A rod-end clevis attachment provides a coupling to rotate about and keep the force transfer along the centerline of the cylinder during actuation. Rod-end clevis attachments are suitable for linear (push or pull) and non-linear load travel. Spherical eye attachments can be used in applications where the load is pushed or pulled in a linear path.

Figure 3: A cap-end female clevis for mounting (A) and a rod-end female clevis attachment (B).

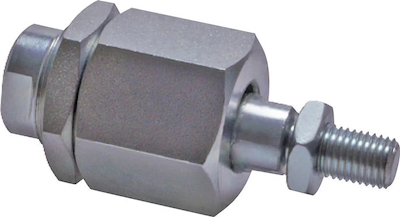

Rod-end floating joint

Rod-end floating joints (Figure 4), also called rod-end alignment couplers, absorb off-centering between the pneumatic cylinder's body and the load with which the floating joint couples. Floating joints can slide along the cylinder's axis and rotate around it. Therefore, a floating joint can adapt to both radial and axial misalignment. Using a floating joint has the following advantages:

- Centering between the pneumatic cylinder and the load is unnecessary

- There is no need for precise machining accuracy

- Suitable for high tensile stresses

- The installation time is low because there is no need for very precise installation

Application

Rod-end floating joints are typically used when misalignment between the pneumatic cylinder and load is likely or where precise movement is necessary. For example:

- Automation and robotics

- Alignment tasks

- Conveyor systems

- Materials handling

- Assembly and production lines

Figure 4: A rod-end floating joint.

Selecting between rod-end accessories

Selecting between rod-end accessories may come down to how the pneumatic cylinder attaches to the load. For example, if the connection point on the load is a bolt, then the user will likely need to use a clevis to connect the cylinder to the load.

Choosing between a spherical eye and a floating joint, which both allow for misalignment and multi-directional movement, comes down to loads and stress. A floating joint can absorb both axial and radial loads, whereas a spherical eye cannot absorb axial loads. Floating joints also better minimize stress on the pneumatic cylinder. Therefore, floating joints are preferable to spherical eyes for heavy or high-stress loads.