A Guide for Selecting a Pressure Gauge

Figure 1: A vacuum pressure gauge

A pressure gauge measures a system's media pressure. Pressure gauges are applicable in many industries where monitoring system pressure is essential. They allow an operator to closely monitor and troubleshoot a system's pressure. For example, pressure gauges can help an operator determine if there is a leak in the system. Depending on the industry and application (e.g., hydraulic, water, vacuum, swimming pool), there are a wide variety of pressure gauge designs & options available. This article covers the parameters to consider when selecting a pressure gauge. To learn more about how they work, read our pressure gauge overview article.

Selection Criteria

- Digital vs analog reading

- Gauge type

- Pressure gauge material

- Fluid temperature

- Pressure range

- Dry vs liquid-filled

- Environmental conditions

- Cabinet size

- Accuracy class

- Mounting method

- IP rating

- Connection size

View our online selection of pressure gauges!

1. Digital vs analog reading

Various digital and analog pressure gauges are available, making each type suitable for most pressure reading tasks. Use the chart below for a general comparison between the two types.

| Digital pressure gauge | Analog pressure gauge |

|

|

Figure 2: A digital pressure gauge

2. Gauge type

There are many types of pressure gauges. The following are common types:

- Bourdon tube: A bourdon tube gauge is the most widely used pressure gauge with a wide range of designs and excellent sensitivity and accuracy. These gauges are suitable for the pressure of media that do not crystallize and are not highly viscous.

- Diaphragm: A diaphragm pressure gauge is suitable for corrosive, highly viscous, or crystallizing media because most of the gauge's components do not interact with the system media.

- Bellows:Bellows pressure gauges have the advantage of being able to measure absolute and differential pressure without extra components.

3. Pressure gauge material

When making decisions about the material, there are two parts of a pressure gauge to consider: the cabinet and the process connection.

- Process connection: The process connection includes any component directly interacting with the fluid. The specific components depend on the type of pressure gauge but typically include the threads and the sensing element. Standard materials are stainless steel or copper alloy. Material incompatibility can cause issues like corrosion, leading to gauge failure and increased safety risks.

- Cabinet: The cabinet, also called the housing material, has a broader material selection and depends more on the application's environment. Common housing materials for pressure gauges include copper alloys, stainless steel, Inconel, and aluminum.

The following table describes some common materials. Refer to our chemical compatibility chart for further information.

| Stainless steel | Inconel | Aluminum | Copper alloy |

|

|

|

|

4. Fluid temperature

The pressure gauge components must be able to withstand the media’s temperature. For gauges that work with hot media, it is recommended that the gauge be used along with a siphon, cooling tower, or diaphragm seal. The maximum recommended fluid temperatures for the pressure gauge materials are:

- Copper alloys: 60 °C (140 °F)

- Stainless steel: 100 °C (212 °F)

- Inconel: 315 °C (600 °F)

5. Pressure range

The pressure range is the maximum and minimum pressures the gauge can read. Ideally, the gauge has a scale that is twice the system’s working pressure. The working pressure should be at most 75% of the gauge’s scale.

6. Dry vs liquid-filled

Figure 3: A glycerine-filled pressure gauge

A liquid-filled gauge is more expensive than its dry counterpart, but has many benefits. Liquid-filled gauges steady the needle in high-vibration applications, keep internal components lubricated, and increase the life of the gauge. The most common type is glycerine, but silicone is also available. Silicone is suitable for a wider temperature range and doesn't discolor over time. Liquid-filled gauges have the added disadvantage of leakage. Therefore it’s important to choose high-quality gauges.

7. Environmental conditions

When working under extreme ambient temperatures, pressure gauges might need to be isolated. In such a case, a remotely mounted gauge with a diaphragm seal and flexible capillary line can be used. It is recommended to use a snubber in areas where pressure spikes and pulsations are normal. In a moist or humid environment, a liquid-filled pressure gauge is preferred to eliminate the risk of condensation build-up. A pressure gauge with stainless steel, plastic, or a brass cabinet is suitable for outdoor use.

8. Cabinet size

A typical pressure gauge dial ranges in diameter from 6.4 cm to 15.2 cm (2.5 in - 6 in). Choose the most appropriate size based on the space limitations and readability requirements for the application.

9. Accuracy class

The accuracy class indicates the maximum permissible margin of error for the pressure gauge with respect to the maximum scale reading. For example, when reading a 100 bar pressure gauge with accuracy class 1, the deviation from actual pressure is 1%, i.e.,1 bar. The degree of accuracy required may differ in different industries.

10. Mounting method

Pressure gauges typically have mounting either below, on the side, or behind the gauge. Verify the mounting method is suitable for the application by making the gauge easy to read.

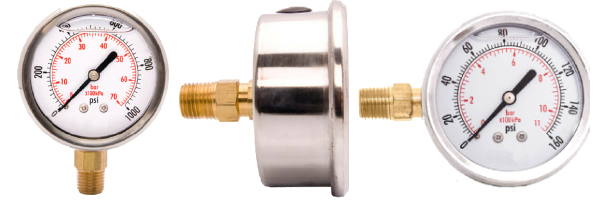

Figure 4: Three different kinds of pressure gauge mounts: a bottom mount (left), a back mount (middle), and a side mount (right).

11. IP rating

IP rating indicates the degree of protection for the pressure gauge against foreign particles such as dust, liquids, moisture, or accidental contacts. Pressure gauges may need to operate in some harsh environmental conditions. For such applications, our pressure gauge provides IP 42, IP 54, and IP 65 protection options.

12. Connection size

Pressure gauge has a wide range of connection size options. Common options are: ⅛ inch, ¼ inch, ⅜ inch, ½ inch, ¾ inch, and M 12x1.5.