Diaphragm Pressure Gauge - How It Works

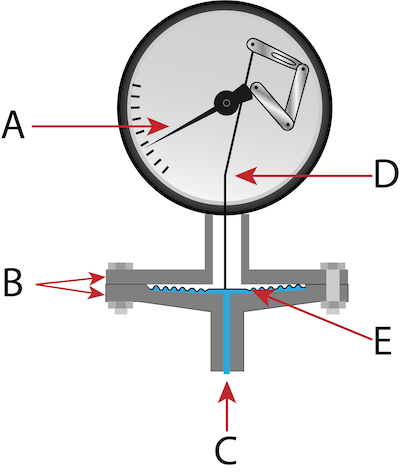

Figure 1: Diaphragm pressure gauge

A diaphragm pressure gauge uses the deflection of a thin, flexible membrane to measure fluid pressure in a system. The diaphragm isolates internal components from the media, making this gauge suitable for corrosive or contaminated liquids or gasses. This gauge is used for low-pressure measurements, such as measuring atmospheric pressure or monitoring pressure in gas canisters. They are also referred to as flexible membrane pressure gauges.

Table of contents

View our online selection of pressure gauges!

Diaphragm pressure gauge working principle

The following list describes the working components and how a diaphragm pressure gauge operates to measure a system’s pressure:

- Pressure inlet: System media enters the pressure gauge at the pressure inlet (Figure 2 labeled C). The inlet has a threaded (e.g., NPT or BSP) or flanged process connection.

-

Diaphragm: The media presses against and proportionally deflects the diaphragm (Figure 2 labeled E). The diaphragm is a thin, circular, flexible, metal disc. It is typically made of stainless steel for corrosion and high-temperature resistance.

- The disc can be corrugated or smooth. Smooth discs are only suitable for small deflections and therefore are unlikely to operate well in industrial applications.

-

Housing: The housing securing the diaphragm has upper and lower components (Figure 2 labeled B). The lower housing connects to the pressure inlet and the upper housing supports the diaphragm in the case of high pressure.

- The two components can be flanged or welded together. Welded connections are preferable for sanitary applications.

-

Pressure element: The pressure element (Figure 2 labeled D) reacts to the diaphragm’s deflection. Typically, the pressure element will be a rack and pinion setup or a bourdon tube setup. For the latter, the pressure element is filled with fluid to transfer pressure changes throughout the element.

- For a digital pressure gauge, a piezoresistive component is typically used.

-

Pointer: Finally, the movement of the pressure element proportionally translates to the pointer's movement so a user can read the system pressure from the pressure gauge.

- For digital pressure gauges, the pressure reading is displayed.

- Regularly calibrate the pressure gauge to ensure proper operation.

Figure 2: Operating principle of a diaphragm pressure gauge: pointer (A), upper and lower housing (B), pressure inlet (C), pressure element (D), and diaphragm (E).

Digital diaphragm pressure gauge

A digital diaphragm pressure gauge is a pressure sensor that utilizes a diaphragm with piezoresistive components. When a medium exerts pressure, the diaphragm bends, altering the cross-sectional area of the piezoresistive elements and leading to a change in their electrical resistance. This generates a voltage difference, which is then processed by the sensor's microprocessor to produce a pressure reading on the digital display.

Applications

There are two reasons to choose a diaphragm seal pressure gauge over other types. The first is when it is necessary for the system's media to not mix or contact the working parts of the gauge past the diaphragm. The second is for measuring low pressures. A diaphragm gauge can accurately measure pressure as low as 16 mbar (0.23 psi). As seen in the list below, a diaphragm pressure gauge is applicable in many different scenarios.

- Pressure measurement in industrial and manufacturing processes, such as in chemical plants and power plants.

- Pressure monitoring in pipelines and other fluid transport systems.

- Pressure testing and calibrating in laboratory settings.

- Pressure measurement in pneumatic and hydraulic systems.

- Pressure monitoring in gas and liquid storage tanks.

- Pressure measurement in HVAC systems, such as in boilers and air conditioning units.

- Pressure monitoring in medical equipment, such as in blood pressure monitors.

Selection criteria

- Material: Use chemically compatible materials for the gauge’s parts that contact the media. Stainless steel is preferred due to its corrosion and high temperature resistance. Whether considering stainless steel or a different material (e.g., brass), see our chemical compatibility chart for more detail on material compatibility.

- Pressure ranges: A diaphragm gauge must accurately display the system's maximum and minimum operating pressures. The system's maximum working pressure should not exceed 75% of the gauge's full-scale range and 65% of the pulsating range.

- Temperature range: Select a gauge with material that can withstand the working temperature. In general, diaphragm pressure gauges can operate well between -20 °C and 100 °C (-4 °F and 212 °F). Always check a gauge’s operating temperature range before using it.

- Diaphragm size: System pressure and diaphragm diameter have an inverse relationship. Low pressures require larger diameter diaphragms, so there is more surface area for the system media to press against.

- Housing seal: Whether the housing around the diaphragm is two flanges or a welded seal depends on the application. Sanitary applications that require further protection against leaking typically use a welded seal.

For more tips and selection criteria on choosing the correct pressure gauge read our selection guide for pressure gauges. To learn more about pressure gauges, read our pressure gauge overview article.

FAQs

How does a diaphragm pressure gauge measure pressure?

System pressure proportionally deforms the diaphragm in the gauge, which translates to movement of the needle on the dial.

Are diaphragm pressure gauges suitable for low pressure?

Yes. Diaphragm pressure gauges with large diameter diaphragms are excellent for accurately measuring minute changes in low pressure systems.