Residential & Commercial Boiler Pressure Gauges

Figure 1: An illustration of a hot water boiler pressure gauge. The green zone indicates normal operating pressures.

A boiler pressure gauge measures the pressure in a boiler. When water heats up, it expands rapidly and occupies a larger space. The boiler pressure gauge reflects the pressure in the vessel during this expansion, regulating the boiler’s operation and helping to avoid potentially hazardous situations. This article focuses on boiler pressure gauges in domestic and commercial applications.

Table of contents

View Tameson's online selection of pressure gauges

Operating principle

A hot water (hydronic) boiler pressure gauge is usually on the front of the boiler. It indicates the pressure of the water leaving the boiler. The gauges are generally calibrated in three sections that show when the pressure is too low, too high, or correctly pressurized. Most domestic and commercial hot water boilers have an operating pressure between 1 and 2 bar (14.5 - 29 psi). However, an industrial boiler for steam production can have much higher pressure gauge readings.

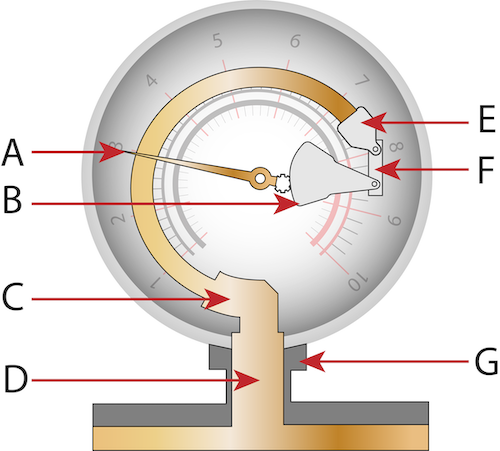

Figure 2: The bourdon tube: indicator needle (A), sector gear (B), stationary end of bourdon tube (C), inlet pipe (D), moving end of bourdon tube (E), pivot and pivot pin (F), and socket block (G).

Boiler pressure gauges operate on the bourdon tube principle of pressure measurement. These gauges have the following components as seen in Figure 2:

- Indicator needle (A): The indicator needle moves with the sector gear to indicate the gauge’s pressure reading.

- Sector gear (B): The sector gear oscillates as the bourdon tube moves, thereby moving the indicator needle.

- Stationary end of bourdon tube (C): Pressurized media flows into the stationary end of the bourdon tube, thereby causing the tube to move towards a straight shape.

- Inlet pipe (D): Pressurized media flows into the pressure gauge through the inlet pipe.

- Moving end of bourdon tube (E): The moving end of the bourdon tube controls the oscillation of the sector gear.

- Pivot and pivot pin (F): The pivot and pivot pin connects the straightening movement of the bourdon tube to the sector gear, translating the movement to rotary movement.

- Socket block (G): The socket block holds the inlet pipe in place and also holds the gauge to the process line.

The bourdon tube principle states that increasing pressure straightens a flattened or circular tube. Our article on pressure gauges offers a more detailed description of how pressure gauges work.

Boiler pressure gauges typically do not have a precise measurement scale (particularly for gauges with the bar scale). These pressure gauges usually only have 0, 1, 2, 3, and 4 bar (0, 10, 20, 30, 40, 50, and 60 psi). On bar scale pressure gauges, it is common to see the dials color-coded to display the correct operating pressure, low pressure, and high pressure. It is not easy to tell the precise measurement, but the colors give a quick guess of the pressure status of the boiler.

Steam boiler pressure gauges

A steam pressure gauge also works with the bourdon tube principle. The primary difference between a steam pressure gauge and a hot water pressure gauge is that residential and commercial steam pressure gauges typically display lower pressures such as 0.03 bar (0.5 psi). During operation, it is normal for a steam pressure gauge to display 0 pressure. This is due to the gauge’s inaccuracy at low and high pressures. Steam boilers use pressure controls to turn boilers on and off between the 0.03 and 0.07 bar (0.5 - 1 psi) range. Some boiler owners or technicians choose to install a low-pressure gauge in addition to the bourdon tube pressure gauge. This second gauge operates at finer pressure scales and will display the actual pressure in the boiler.

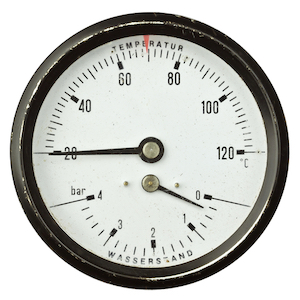

Boiler pressure temperature gauge

Pressure temperature gauges (Figure 3) are for hot water boilers. For typical residential boilers, a pressure temperature gauge reads 0.8 bar (12 psi) when the boiler is cold and 2.1 bar (30 psi) when the boiler is hot. If the pressure in the system exceeds 2.1 bar, a pressure relief valve on the boiler opens. When the boiler turns on, the temperature should be between 49 °C and 71 °C (120 °F and 160 °F). When the boiler cuts off, the temperature should be between 82 °C and 93 °C (180 °F and 200 °F).

Figure 3: A pressure temperature gauge

Application of boiler pressure gauge

The boiler pressure gauge has several functions. Here are some of them:

- Low-pressure indicator: The boiler pressure gauge shows when the pressure in the system is low. Low pressure is usually due to low water levels. Low water levels can be caused by leakages, excess bleeding from the radiator, and incomplete water filling during installation. If leaking and radiator bleeding are ruled out, acquire a filling loop to temporarily connect the boiler to the mains water supply. Fill until the pressure gauge reads 1.5 bar (22 psi).

- High-pressure indicator: If the boiler is too full or the filling valve is not closed correctly, the boiler pressure gauge will indicate high pressure. High pressure is typically above 2 bar for domestic and commercial applications. In space heating applications, reduce pressure by carefully bleeding the radiator while monitoring the pressure gauge when the boiler is running. In other applications, a pressure relief valve regulates high pressure in the boiler. A faulty pressure relief valve can also cause a high-pressure indicator. The most common fix for high pressure in a boiler is to bleed radiators by slightly opening the pressure relief valves.

- Maintenance: Inconsistent pressure reading during boiler operation potentially indicates the need for boiler maintenance. These inconsistencies may be caused by blockages in the pipe, leakages, a faulty burner or electrical heating coils. To learn about maintaining a boiler pressure gauge and other pressure gauges, please read our pressure gauge maintenance and troubleshooting article.

Figure 4: A boiler pressure gauge

Selection criteria

- Measuring range: The measuring range of a boiler pressure gauge is much smaller than most other applications, particularly for domestic and commercial applications. The typical range is from 0 – 4 bar (0 – 60 psi). Some gauges are 0 – 3 bar (0 – 45 psi). The dial is sometimes calibrated with green and red colors to indicate low pressure, high pressure, and standard operating conditions. Red on the dial indicates low- and high-pressure, while the green color indicates normal operating conditions (indicated on the boiler).

- Connection size and type: Pressure gauges have different types of connections, including NPT, BSP, and DIN. Gauges with a 114 mm (4.5 in) dial size typically have a 13 mm (0.5 in) connection.

- Connection material: Boiler pressure gauges have different connection materials, such as brass and copper alloy. Ensure the selected material is compatible with the process and holding socket. Please check out the material compatibility chart before deciding.

- Connection location: Possible connection points are below, above, or at the rear of the gauge. Consider the available space in the system and how it affects the connection location.

- Unit of measurement: For gauge pressure measurement, it is common to have both bar and psi.

- IP protection: The IP rating is essential, primarily if the boiler pressure gauge in an environment with dust or water splashes. Higher IP ratings will mean a higher cost of the gauge.

- Digital reading:Digital display pressure gauges are available to measure boiler pressure. Boiler pressure gauges with digital displays can often transmit the reading to a remote controller. However, most boiler pressure gauges have a dial indicator and do not require external power to operate.

Learn more about pressure gauge selection criteria in our selection guide.

FAQs

Are there different types of pressure gauges?

There are many different types of pressure gauges, including the bourdon tube gauge, bellows pressure gauge, hygienic pressure gauges, and diaphragm pressure gauges.

What should pressure read on a commercial boiler pressure gauge?

Hot water boiler pressure gauges typically read between 1-2 bar (14.5 - 29 psi). Steam boiler pressure gauges typically read zero because the actual pressure is very low (0.5 psi).