Water Pressure Regulator Overview and Selection Guide

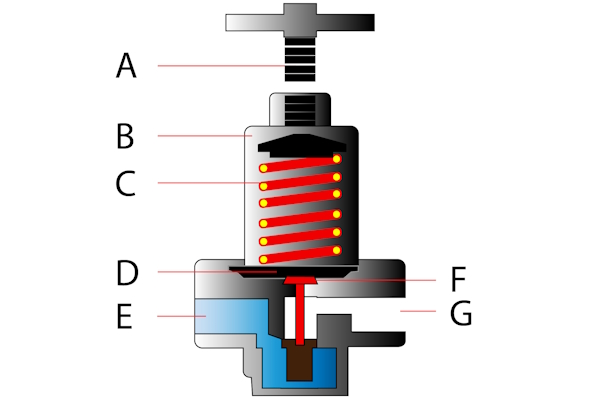

Figure 1: A water pressure regulator

Maintaining proper water pressure in residential, commercial, and industrial systems is essential for the efficient and safe operation of water delivery. A water pressure regulator valve plays an important role in this process. It controls the water flow and stabilizes the pressure to a set level within the plumbing system.

Table of contents

- Design of a water pressure regulator

- Operating principle

- Common applications

- Limitations

- Selection criteria

- FAQs

View our online selection of water pressure regulators!

Design of a water pressure regulator

The typical design of a water pressure regulator (Figure 2) uses precision and durability to manage water pressure in a system.

- Adjustment screw (A): Positioned on the top of the regulator, the adjustment screw allows for manual setting of the desired pressure. Turning the screw adjusts the compression on an internal spring.

- Body (B): The body of the regulator, usually made of brass or stainless steel, houses the internal components.

- Adjusting spring (C): The spring exerts pressure on the diaphragm. The tension of the spring is adjustable and determines the downstream pressure.

- Diaphragm (D): The diaphragm is a flexible membrane, often made of rubber or a similar material, which reacts to changes in water pressure. It moves in response to the downstream pressure and the tension of the spring.

- Inlet and outlet ports (E & G): These ports allow the flow of water into and out of the regulator. The flow must go from inlet to outlet (marked by an arrow on the valve body), it cannot be reversed.

- Valve seat (F): Located beneath the diaphragm, the valve seat opens or closes to regulate water flow. It is crafted to create a watertight seal when closed.

- Strainer or filter: A strainer is usually present at the inlet to prevent debris from entering the regulator, which could affect its operation and lifespan.

- Pressure gauges: Some regulators are equipped with pressure gauges on both the inlet and outlet sides to monitor the pressure difference and confirm the regulator's performance.

Furthermore, it's common for specific features to be written directly on the housing. For example, the valve in Figure 1 has 3/4" thread dimensions.

Figure 2: The typical design of a water pressure regulator: adjustment screw (A), body (B), adjusting spring (C), diaphragm (D), inlet port (E), valve seat (F), and outlet port (G). This figure does not show other components (e.g., filter and pressure gauges).

Operating principle

The operating principle of a water pressure regulator involves the balance between mechanical force and fluid dynamics. The regulator's main function is to automatically reduce and stabilize the incoming water pressure from the main supply to a lower, more manageable pressure that can be safely utilized in a home or commercial building's plumbing system. Here's how it works:

- Inlet pressure: Water enters the regulator through the inlet port. This water is at a higher pressure, which is often too great for the plumbing system to handle safely.

- Diaphragm and valve action: The incoming water applies pressure against the diaphragm. The other side of the diaphragm is connected to the spring and the valve seat.

- Spring tension: The spring above the diaphragm opposes the water pressure.

- Pressure balancing: As the inlet water pressure forces the diaphragm down, the valve seat attached to the diaphragm opens, allowing water to flow through. If the inlet pressure increases, the additional force on the diaphragm compresses the spring further and opens the valve seat more to let more water through until the pressure is balanced. Conversely, if the inlet pressure decreases, the spring pushes the diaphragm up, causing the valve seat to reduce the opening and limit the flow of water.

- Outlet pressure: The water then exits the regulator through the outlet port. The outlet pressure is controlled by the balance between the diaphragm and spring mechanism and is independent of the inlet pressure fluctuations.

- Downstream control: The outlet pressure remains constant because any change in downstream pressure causes the diaphragm to adjust the opening of the valve seat, increasing or decreasing the flow to maintain the set pressure.

Common applications

Water pressure regulators are widely used across various settings due to their ability to control and maintain a stable water pressure output. The common applications of these devices span residential, commercial, and industrial environments:

-

Residential applications:In homes, water pressure regulators are installed to manage the pressure of the water supplied by the municipal line. They protect household plumbing and appliances from damage due to high pressure, reduce the risk of leaks, and help to conserve water. Learn more in our selection guide for home water pressure regulators.

- Appliance protection: Many home appliances, such as washing machines, dishwashers, and water heaters, have specific pressure requirements for safe operation. Regulators ensure these appliances receive water at the correct pressure to prevent malfunctions and extend their lifespan.

- Irrigation systems: Regulators are integral in irrigation systems to maintain optimal water pressure for sprinklers and drip irrigation lines, ensuring even distribution of water, preventing erosion and runoff, and enhancing water conservation.

- Commercial settings: In commercial buildings, such as hotels, hospitals, and office complexes, water pressure regulators are essential for managing the complex water systems that service numerous floors and facilities, ensuring consistent water pressure throughout the building.

- Fire suppression systems: Regulators are used to control the water pressure in fire suppression systems to prevent damage to the pipes and ensure that the sprinkler systems operate effectively in the event of a fire.

- Manufacturing and industrial plants: These settings often require precise water pressure control for various processes. Regulators are used to ensure that the water used in manufacturing processes is at the correct pressure to protect equipment and maintain production standards.

- Municipal water supply: Water utilities use pressure regulators to manage the distribution of water across the city or town, especially in areas with varying elevations where pressure can significantly fluctuate.

- Food and beverage industry: For food processing and beverage production, consistent water pressure is vital for the operation of machinery and for ensuring product quality and safety.

- HVAC systems: Heating, ventilation, and air conditioning systems sometimes use water as a heat transfer medium. Regulators help to maintain the correct water pressure within these systems for efficient heating and cooling.

Limitations

- Lifespan and wear: Over time, the internal components of a pressure regulator, such as the diaphragm, spring, and valve seat, can wear out or degrade. This deterioration can lead to a failure to maintain the set pressure, necessitating repair or replacement of the unit.

- Adjustment range: Each regulator has a specific adjustment range, and it cannot regulate pressure outside of this predefined range. If the incoming water pressure exceeds the maximum limit the regulator can handle, it may not function correctly.

- Flow restrictions: Regulators can sometimes restrict water flow, particularly if they are not sized correctly for the plumbing system. An undersized regulator can lead to a decrease in flow rate, affecting the performance of water fixtures and appliances.

- Single-direction regulation: Standard water pressure regulators are designed to reduce and control pressure in one direction only. They do not increase pressure when the incoming pressure is too low.

- Freezing temperatures: In areas with freezing temperatures, regulators can be damaged if water inside them freezes, expanding and potentially cracking the housing or internal components.

- Debris sensitivity: Regulators can be sensitive to dirt, debris, and sediment in the water supply, which can clog or damage the regulator and affect its performance.

- Pressure fluctuations: Sudden and extreme fluctuations in the incoming water pressure can challenge the regulator's ability to maintain a stable output, possibly leading to brief periods of over- or under-pressurization.

- No backflow prevention: Pressure regulators do not prevent backflow. Additional backflow prevention devices are needed to protect the potable water supply from contamination.

Selection criteria

Choosing the right water pressure regulator requires careful consideration of several factors to ensure it meets the needs of the plumbing system it will serve. The following selection criteria are essential when selecting a water pressure regulator. For further information on residential plumbing systems, read our home water pressure regulator selection guide.

- Pressure range: The regulator must be capable of handling the maximum inlet pressure from the water supply while providing the desired range of outlet pressure for the system. For example, in typical residential plumbing systems that require water pressure regulators, the incoming water pressure may be 4.8 bar (70 psi) or above; the water pressure regulator needs to adjust this pressure to a value between 2.7 and 4.1 bar (40 - 60 psi).

- Flow rate: The regulator should accommodate the system's maximum flow rate requirements without causing a significant drop in pressure or restricting water flow to fixtures and appliances. Learn more about calculating flow rate in our Kv and Cv calculator articles.

- Size: Proper sizing is critical for performance. The regulator size should match the pipe size of the system to maintain adequate flow and pressure.

- Material: The construction material of the regulator should be compatible with the type of fluid it will be regulating, and it should be suitable for the environmental conditions where it will be installed. Common materials include brass, stainless steel, and plastic.

- End connections: The regulator should have the appropriate end connections, such as threaded or flanged, to fit the existing piping system.

- Temperature range: Ensure that the regulator can operate within the temperature range of the water in the system.

- Certification and standards: The regulator should meet relevant industry standards and certifications, ensuring safety, reliability, and compliance with local codes and regulations. For example, water pressure regulators used in agricultural systems may need to adhere to ISO 10522.

FAQs

How does a water pressure regulator work?

A water pressure regulator reduces and stabilizes incoming high pressure using an adjustable spring and diaphragm mechanism.

How do I adjust my water pressure regulator?

Turn the regulator's adjustment screw clockwise to increase pressure or counterclockwise to decrease it.