Pneumatic Actuators From Festo

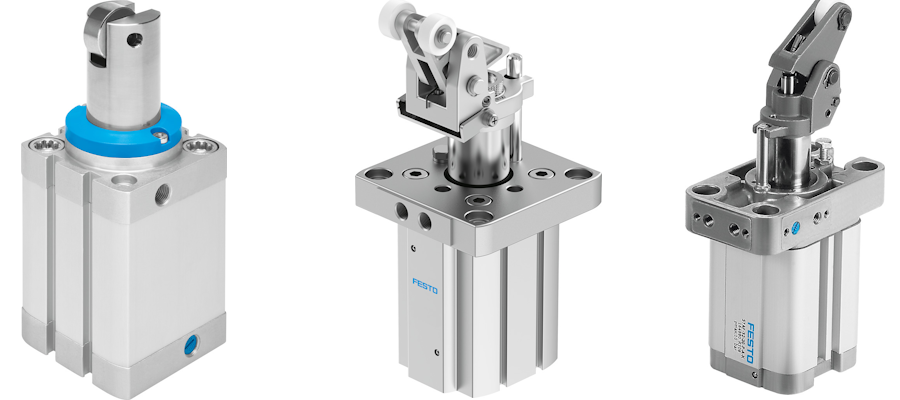

Figure 1: Festo pneumatic stopper cylinder: DFSP (left), DFST-G2 (middle), and STAF (right)

A pneumatic actuator is a device that converts the energy of compressed air into mechanical motion. This motion can be linear or rotary, depending on the design of the actuator. Festo offers a diverse range of pneumatic actuators, including linear cylinders, rotary actuators, and grippers. This article explores the wide range of Festo actuators, focusing on their unique features and suitability for different industrial needs.

Table of contents

- Piston rod cylinders

- Rodless cylinders

- Rotary actuators

- Stopper cylinder

- Multi-position cylinders

- Guiding units for pneumatic cylinders

- Clamping cylinders

- Rotary index tables

- Quarter turn actuators for process automation

Piston rod cylinders

ISO standard cylinders

ISO standard pneumatic cylinders are designed to meet internationally recognized specifications for quality, safety, and performance, ensuring consistency and interchangeability across different manufacturers.

- ISO 21287 compact pneumatic cylinders are suitable for high-performance applications in limited spaces and offer force up to 1500 N, with easy replacement across brands.

- ISO 15552 pneumatic cylinders are characterized by their rectangular prism shape, versatile mounting options, and repairable design, making them a popular choice in industrial automation.

- ISO 6432 mini pneumatic cylinders have small, round profiles ideal for compact and precise applications, and available in materials like aluminum and stainless steel for various environments.

Figure 2: A double-acting ISO 21287 pneumatic cylinder (left), ISO 15552 (middle) and ISO 6432 pneumatic cylinders (right)

Round cylinders

Round cylinders EG are miniature single-acting pneumatic cylinders with a piston rod at one end. They are designed for compact assemblies, such as testing systems for keyboards or mobile phones. They are slim and have a corrosion-resistant design with low mass (2 to 24 grams), making them ideal for installation in tight spaces. They come in various piston diameters (2.5 to 6 mm) and stroke lengths (5 to 25 mm), with barbed fittings for standard plastic tubing, ensuring easy integration and reliable performance in small-scale applications.

Figure 3: Festo round cylinder EG-PK

Stainless steel cylinders

Stainless-steel cylinders are designed for applications requiring high resistance to corrosion and harsh operating conditions. Key features include the use of high-alloy, stainless austenitic chrome-nickel and chrome-nickel-molybdenum steels, which protect against chemical and electrochemical stress, as well as damage from cleaning agents or disinfectants. These cylinders are suitable for environments with extreme conditions, such as the maturing cellars of cheese factories, and are assembled with NSF-H1 compliant grease and wipers, making them ideal for use in the food industry.

Figure 4: Festo stainless steel cylinder CRDSNU

Compact, short stroke, and flat cylinders

- Compact cylinders: Compact cylinders are designed for space-critical applications, offering a very compact design with reduced housing length and width. They feature elastic cushioning rings for end-position cushioning and options for position sensing, making them suitable for various industrial uses, including those requiring special material properties.

- Short-stroke cylinders: Short-stroke cylinders are ideal for clamping tasks with short strokes, providing rapid response and large clamping forces relative to their size. They come in both double-acting and single-acting variants, with integrated sensor slots for proximity sensors and standardized mounting patterns, making them versatile for various automation applications.

- Flat cylinders: Flat cylinders offer a low-profile design with both single-acting and double-acting options, including through piston rods and hollow piston rods. They are suitable for applications requiring a compact form factor, featuring adjustable pneumatic cushioning and compatibility with proximity sensors for precise position sensing, making them ideal for tight spaces and precise operations.

Cartridge cylinders

Cartridge cylinders are compact pneumatic actuators designed for minimal installation space and easy integration without the need for additional mounting attachments. They are single-acting, having a range of piston diameters (6 to 16 mm), and stroke lengths (5 to 15 mm). They are constructed with high-alloy steel piston rods, brass nickel-plated housing, and polyacetal covers, and can be mounted in any position using lock nuts or accessories.

Figure 5: Festo cartridge cylinder EGZ

Rodless cylinders

Festo's linear drives DLGF are highly versatile, rodless actuators designed for space-saving installations in automation systems. These drives are ideal for applications requiring precise linear motion, such as pick-and-place units and long-stroke grippers. The DLGF series offers three pneumatic connection options-left-hand, right-hand, or both ends, and even from below, providing flexibility in installation.

They have a very flat design, enabling compact setups, and two cushioning types: PPS self-adjusting pneumatic cushioning and external hydraulic shock absorbers. The drives support direct mounting of loads and devices on the slide, with recirculating ball bearing guides available for high precision and minimal backlash. With piston diameters ranging from 20 to 40 mm and stroke lengths from 50 to 1000 mm, these drives are suitable for small to medium loads.

Figure 6: Festo linear drive DLGF

Rotary actuators

Semi-rotary drives

Semi-rotary drives provide precise and controlled limited rotational movement, typically less than 360 degrees, in various industrial applications. These drives are essential in scenarios where full rotation is unnecessary or impractical, such as valve actuation, material handling, and automation systems. Festo's pneumatic semi-rotary drives offer vane and rack-and-pinion mechanisms to suit different needs.

Figure 7: Festo semi-rotary drive DRRD with gear rack and pinion

Swivel/linear actuators

Swivel/Linear units DSL-B combine rotational and linear motion in a single compact unit, ideal for applications requiring precise positioning and movement. These units are commonly used in automation systems, material handling, and assembly processes. The DSL-B units offer high repetition accuracy due to fixed stop cushioning components and can achieve swivel angles up to 270° and linear strokes up to 200 mm.

Key features include individual or simultaneous control of both movements, high rotational energy absorption via self-adjusting shock absorbers, and compact sensing of motion through proximity switches. Designed for easy integration, they feature supply ports at one end for straightforward tubing connections and various mounting options.

Figure 8: Swivel/Linear unit DSL

Stopper cylinder

Pneumatic stopper cylinders (Figure 1) are essential components in modern transport systems, used to regulate movement and halt workpieces or carriers at specific points on conveyor systems or assembly lines. These cylinders ensure smooth and safe operation by effectively stopping moving parts, making them crucial for maintaining workflow efficiency and safety in various industrial applications. There are different models of pneumatic stopper cylinders,like DFSP, DFST-G2, and STAF, each designed to meet specific industrial needs.

Multi-position cylinders

Multi-position pneumatic cylinders are versatile actuators capable of moving to several predefined positions, unlike standard cylinders that only fully extend and retract. This is achieved by connecting two or more standard cylinders with the same piston diameter in a specific arrangement. By controlling the extension and retraction of each cylinder, multiple positions can be achieved, making these cylinders economical compared to complex electronic control systems. Festo's multi-position cylinder ADNM, for instance, connects 2 to 5 cylinders in series with different stroke lengths, achieving up to five distinct positions.

These cylinders are crucial in applications requiring precise positioning, such as material handling, assembly lines, and packaging processes. They offer significant flexibility and cost-efficiency, especially when configured using Festo's multi-position assembly kits like DPNA, DPNC, and DPVU. These kits simplify the assembly process, ensuring compatibility and ease of integration.

Figure 9: Festo multi-position cylinder

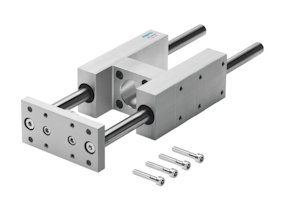

Guiding units for pneumatic cylinders

A guide unit for pneumatic cylinders provides additional support and alignment to the piston rod, ensuring smoother and more precise linear motion. These units help manage and distribute the load more effectively, preventing the piston rod from bending or deflecting under heavy loads. This is crucial in applications requiring high accuracy and repeatability, and where the cylinder is subjected to side or off-center loads. By reducing side loads, guide units minimize wear and tear on the cylinder's seals and bearings, thereby extending the lifespan of the pneumatic cylinder.

Festo offers the FENG series of guide units, which include options for both plain-bearing and recirculating ball bearing guides. These guide units are compatible with various Festo pneumatic cylinders such as the DNC, DNCB, DNCV, and DNG models.

Guide units are widely used in automation and robotics, material handling, packaging machinery, and machine tools. They provide the necessary support to ensure precise and repeatable movements, manage loads effectively, and maintain the accuracy and stability required in high-force or high-speed operations.

Figure 10: A Festo FENG pneumatic cylinder guide unit

Clamping cylinders

Clamping cylinders are essential in industrial automation for securely holding or clamping workpieces, either directly through a pneumatically operated clamping element or via kinematic mechanisms. These cylinders can achieve high holding forces with minimal energy input due to their efficient design. They are typically integrated with various equipment such as pneumatic slide rails, robotic arms, and other motion mechanisms, making them versatile for applications like welding, assembly, and material handling.

There are a diverse range of clamping cylinders, including clamping modules, linear/swivel clamps, and hinge cylinders.

- Clamping modules, available in rectangular and round designs, are ideal for tight spaces and harsh environments, providing clamping forces up to 1640 N.

- Linear/swivel clamps combine linear and swivel motions, suitable for versatile clamping tasks in welding and compact spaces, with clamping forces up to 1600 N.

- Hinge cylinders, designed for high clamping forces and welding processes, feature easy mounting and integrated flow control, making them perfect for automotive and industrial applications.

Each type is engineered to meet specific industrial needs, ensuring reliable and efficient operation.

Figure 11: Festo linear/swivel clamping cylinder

Rotary index tables

A rotary index table is a precision positioning device used to rotate workpieces to specific angles for machining or inspection tasks, enhancing efficiency and precision in manufacturing processes. The DHTG rotary index table is designed for tasks such as swiveling or separating workpieces in industrial settings.

Key features of the DHTG include variable indexing and reversible rotation, allowing for flexible operation and precise control over movement. It is available in multiple diameters (65, 90, 140, and 220 mm) to accommodate a range of applications. The robust mechanical system ensures durability and reliability, while integrated functions like overload protection, sensor monitoring, and cushioning adjustment contribute to smooth and efficient performance. The DHTG's easy planning and commissioning make it a user-friendly choice for integrating into existing systems, simplifying setup and maintenance.

Figure 12: Festo DHTG rotary index table

Quarter turn actuators for process automation

The DFPD series and DAPS are types of quarter turn actuators used to automate the opening and closing of valves, such as butterfly valves, ball valves, and dampers, in various industrial processes.

- The DFPD series uses a rack and pinion mechanism to provide consistent torque throughout its 90° rotation, making it ideal for precise control in applications requiring reliable and long-lasting performance. It features a sturdy aluminum housing and is available in versions that can rotate up to 180°.

- The DAPS actuator is designed for the process industry, offering high breakaway torque and a compact, robust design. It can be equipped with a manual handwheel for emergency operation and is available in a corrosion-resistant stainless steel version, making it suitable for harsh environments. It also complies with safety standards, including the EU Explosion Protection Directive (ATEX).

Also, there are connecting cables to link pneumatic actuators and other automation components, ensuring reliable electrical connections and protection in various environmental conditions. It is suitable for both indoor and outdoor use, offering features like high protection ratings (IP65, IP67, IP69K), a flexible installation position, and compatibility with compressed air systems.