What is a Solenoid Valve and How Do They Work

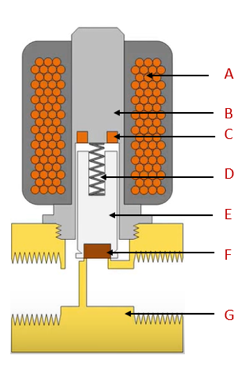

Figure 1: 2/2-way solenoid valve

A solenoid valve is an electrically controlled valve used to allow or prevent the flow of media through it. The basic principle of operation is a plunger that moves up and down based on the magnetic field generated from the electrical solenoid. This plunger either opens or closes an orifice that the media flows through. There are different circuit functions, designs, and construction material allowing them to be selected and designed for specific applications. They can be remotely and automatically controlled, making them ideal for a wide variety of industries from water treatment, automotive, and food processing applications.

Solenoid valve fast facts

- Clean liquids/gasses only: Solenoid valves are designed to be used with clean liquids and gasses.

- Precise flow control: Accurate fluid/gas regulation, ideal for sensitive processes in medical devices and manufacturing.

- Fast response time: Rapid opening/closing actions, vital for safety applications and swift reaction to hazards.

- Long service life: Durable, reliable performance reduces maintenance needs and withstands demanding usage.

- Wide range of applications: Versatile for various industries, including water treatment, automotive, and food processing.

View our online selection of solenoid valves!

Table of contents

- How does a solenoid valve work?

- Solenoid valve types

- Circuit functions of solenoid valves

- Direct, indirect, and semi-direct acting solenoid valves

- Solenoid valve approvals

- Special solenoid valve features

- Selection criteria

- Solenoid valves for pneumatics and hydraulics

- Other solenoid valve applications

- FAQs

How does a solenoid valve work?

Figure 2: Components of a solenoid valve: coil (A), armature (B), shading ring (C), spring (D), plunger (E), seal (F), and valve body (G).

A solenoid valve consists of two main components: a solenoid and a valve body (G). A solenoid has an electromagnetically inductive coil (A) around an iron core at the center called the plunger (E). AC coils have a shading ring (C), which prevents vibration and humming.

At rest, the valve can be normally open or normally closed. In the de-energized state, a normally closed valve is closed. When current flows through the solenoid, the coil is energized and creates a magnetic field. This creates a magnetic attraction with the plunger, moving it and overcoming the spring (D) force. The plunger lifts so that the seal (F) opens the orifice and allows the flow of the media through the valve. A normally open solenoid valve works in the opposite way.

Solenoid valves are used in a wide range of applications, with high or low pressures and small or large flow rates. These solenoid valves use different operating principles that are optimal for the application. The three most important ones are explained in this article: direct acting, indirect acting, and semi-direct acting operation.

Solenoid valve types

Normally closed solenoid valve

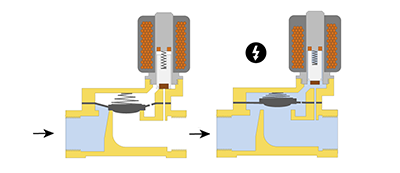

For a normally closed (NC) solenoid valve, the valve is closed when de-energized, which prevents the media from flowing through it. When current is sent to the coil, it creates an electromagnetic field that forces the plunger upwards overcoming the spring force. This unseats the seal and opens the orifice allowing the media the flow through the valve. Figure 3 shows the operating principle of a normally closed solenoid valve in the de-energized and energized states. A normally closed solenoid valve is ideal for applications that require the valve to be closed for long periods of time as this is then more energy efficient. They can also be used for safety reasons, if the application requires the valve to be closed with no power for safety reasons (e.g. gas appliances).

Figure 3: Operating principle of normally closed solenoid valve: de-energized (left) and energized (right).

Normally open solenoid valve

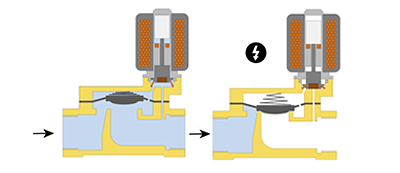

For a normally open (NO) solenoid valve, the valve is open when de-energized, which allows the media to flow through it. When current is sent to the coil, it creates an electromagnetic field that forces the plunger downwards overcoming the spring force. The seal sits in the orifice and closes it, which prevents media from flowing through the valve. Figure 4 shows the operating principle of a normally open solenoid valve in the de-energized and energized states. A normally open solenoid valve is ideal for applications that require the valve to be open for long periods of time as this is then more energy efficient. They can also be used for safety reasons, if the application requires the valve to be open with no power for safety reasons (e.g., to prevent overpressure).

Figure 4: Operating principle of normally open solenoid valve: de-energized (left) and energized (right).

Bi-stable solenoid valve

A bi-stable or latching solenoid valve can be switched by a momentary power supply. When de-energized, the valve stays in the position it switched to. Therefore, it is not normally open or normally closed as it stays in the current position when no power is applied. They accomplish this by using permanent magnets, rather than a spring. This gives the benefit of reduced power consumption.

Circuit functions of solenoid valves

Solenoid valves are used to close, open, dose, distribute or mix the flow of gas or liquid in a pipe. The specific purpose of a solenoid valve is expressed by its circuit function. For an in-depth understanding of symbols and understanding circuit function diagrams, view our valve symbol page.

2-way solenoid valve

2-way solenoid valves have two ports, an inlet and an outlet. Flow direction through the valve is critical to ensure proper operation. There is typically an arrow on the body of the valve that indicates the flow direction.

- 2-way solenoid valves are used to allow or block flow.

3-way solenoid valve

A 3-way solenoid valve typically has three ports, each designated for a specific function. Here are the common designations for these ports:

- P (pressure) port or inlet port: This is where the pressurized fluid or gas enters the valve.

- A (actuator) port or outlet port: This is the working port connected to the device or actuator that the valve is intended to control, such as a single-acting pneumatic cylinder or a process line.

- E (exhaust) port or R (return) port: This port is used to vent the fluid or gas from the actuator or device back to the atmosphere or a reservoir when the valve is switched to the exhaust position. In some systems, this port might also serve as an alternative inlet or outlet, depending on the valve's configuration and application.

The specific function of the ports depends on the state of the solenoid valve (energized or de-energized) and the design (normally closed or normally open).

- Normally closed (NC): When the valve is de-energized, the P port is closed, and there is no flow allowed from the inlet to the outlet. The A port is typically connected to the E or R port, allowing the actuator to exhaust. When energized, the valve opens the flow from the P port to the A port and closes off the E or R port.

- Normally open (NO): When the valve is de-energized, the P port is open to the A port, allowing flow from the inlet to the outlet. The E or R port is closed. When energized, the valve switches to close the flow from P to A and opens the connection between A and E or R, allowing the actuator to exhaust.

Direct, indirect, and semi-direct acting solenoid valves

Direct acting

A direct-acting solenoid valve uses the solenoid to open or close, without the need for differential pressure. These valves are often used for controlling the flow of gas or liquid in a system. Direct-acting solenoid valves have the fastest operation, are reliable, and have a compact design.

Indirect acting

Indirect-acting solenoid valves, also known as servo-operated or pilot operated, use pressure differences to operate. They require a minimum pressure differential of about 0.5 bar. These valves include a diaphragm with a small hole that allows flow from the inlet to the outlet when the solenoid is energized and the pressure drops. This system amplifies the pressure, allowing a small solenoid to control a large flow rate. Indirect solenoid valves are used in applications with sufficient pressure differential and high desired flow rates, and they only allow media flow in one direction.

Semi-direct acting

Semi-direct acting solenoid valves blend the features of direct and indirect valves, enabling operation from zero bar while managing high flow rates. These valves resemble indirect valves with a movable membrane, small orifice, and pressure chambers on both sides, but the solenoid plunger is directly connected to the membrane. When the plunger lifts, it directly opens the valve and a second orifice, causing the pressure to drop and the membrane to lift. This results in a valve that can operate from zero bar and manage large flow rates. These semi-direct operated valves, also known as assisted-lift solenoid valves, often have more powerful coils than indirect-operated valves.

Materials

The materials used to construct solenoid valves are ensure it will function properly in the application without causing contamination. The media that flows through the valve comes into contact with both the housing and seal material. If an aggressive or contaminated media is used, a media-separated solenoid valve may be a good solution.

Housing Material

The solenoid valve's housing and body material must be compatible with the media. Common options are brass, stainless steel, PVC, aluminum, and cast iron. See our quick guide below, but refer to our housing material guide and media compatibility chart for more information.

- Brass: Brass has good corrosion resistance with neutral media, such as water.

- Stainless steel: Stainless steel has good chemical, temperature, and pressure resistance.

- PVC: PVC and polyamide are commonly used as they are cost efficient. They are also used in high-end applications with aggressive chemicals.

- Aluminum: Aluminum's lightness, strength, and thermal properties make it a cost-effective and reliable choice for solenoid valve housings.

- Cast iron: Cast iron provides a strong, wear-resistant, and cost-effective housing for solenoid valves, with added vibration damping suitable for tough industrial applications.

Sealing Material

The solenoid valve's sealing material must also be compatible with the media. NBR, EPDM, FKM (Viton), and PTFE (Teflon) are common options. See our quick guide below, but refer to our seal material guide and media compatibility chart for more information.

- NBR: NBR seals have excellent oil and fuel resistance, making them ideal for petroleum-based applications.

- EPDM: EPDM seals have great resistance to weathering, ozone, and steam, suiting them for outdoor and hot water applications.

- FKM (Viton): FKM seals have high chemical and heat resistance, which is perfect for harsh chemical and high-temperature environments.

- PTFE (Teflon): PTFE seals have exceptional chemical inertness and a wide temperature range, making them versatile for aggressive media and extreme conditions.

Solenoid valve approvals

Depending on the application, certain approvals for the valve may be needed. Having a valve with a certain approval ensures it meets the demands of the application. Common approvals are:

- UL/UR: Underwriters Laboratories inspects and certifies products with respect to their safety

-

Drinking water: Ensures it is suitable for drinking water purposes. For more information, refer to our drinking water application page or view our water solenoid valves article. Common drinking water approvals are:

- Kiwa: Drinking water approval for the Dutch market.

- NSF: Drinking water approval for North America.

- WRAS: Compliance with Water Supply Regulations in UK or Scottish Byelaws for material safety and mechanical testing.

- KTW: Approval for plastics and non-metallic materials for use with potable water in Germany.

- ACS (Attestation De Conformite Sanitaire): Drinking water approval for France.

- Watermark: Certification for plumbing and drainage products for sale in Australia and New Zealand.

- FDA: US Food and Drug Administration

- ATEX version: ATEX certification is provided for explosion protection. For more information, refer to ATEX Directives for valves and fittings.

- CE certification: CE certification signifies conformity with high safety, health, and environmental protection requirements for all products in the European Economic Area. For more information, refer to our CE certification page.

- Gas version: Valves for gas applications have DVGW approval for use in gas-burning appliances as automatic shut-off valves. For more information, refer to our Gas Approval Regulation page.

- IP rating: The IP rating of a valve explains its protection to dust and water. For more information, refer to our IP rating page.

Special solenoid valve features

- Electric power reduction: The rated voltage is supplied to the valve for a short period of time to actuate the valve, then it is reduced to a holding voltage that is strong enough to hold the valve in that position while reducing power consumption.

- Latching: Latching or pulse coil version provides a solution for applications with low-frequency switching. The valve is energized by a short electric pulse to move the plunger. A permanent magnet is then used to keep the plunger in that position with no additional spring or magnetic field. This lowers power consumption and heat development in the valve.

- High Pressure: High pressure versions are designed for pressure requirements up to 250 bar.

- Manual override: Optional manual override feature provides better safety and convenience during commissioning, testing, maintenance, and in case of a power failure. In some versions, the valve cannot electrically actuate when the manual control is locked.

- Media separation: Media separation design allows isolation of the media from the valve’s working parts, making it a good solution for aggressive or slightly contaminated media.

- Vacuum: Valves that do not require a minimum pressure differential are suitable for rough vacuums. Universal direct-acting or semi-direct-acting solenoid valves are well suited for these applications. For more stringent leakage rate requirements, special vacuum versions are available.

- Adjustable response time: The time it takes the valve to open or close can be adjusted, typically by rotating screws on the valve’s body. This feature can help prevent water hammer

- Position feedback: The switching status of a solenoid valve can be indicated with an electrical or optical position feedback as a binary or NAMUR signal. NAMUR is a sensor output that indicates the on or off state of the valve.

- Low noise: Valves have a damped design to reduce the noise during the closing of the valve.

Selection criteria

It is essential to understand your application before selecting a solenoid valve. Some important selection criteria are as follows:

- Housing material: Determine valve housing material based on the chemical properties and temperature of the media, but also the environment the valve is in. Common options are brass, stainless steel, PVC, aluminum, and cast iron. Refer to Select the right housing material for your solenoid valve for more information.

- Connection size: Ensure the solenoid valve's port sizes are the same as what the valve will connect to.

- Connector: A solenoid connector is a device that plugs into a solenoid valve to supply it with electricity, and it helps protect the connections from dirt and water.

- Voltage: Determine which voltage the power supply has and select a solenoid valve with a corresponding solenoid.

- Seal material: Seal material should be selected based on the chemical properties and temperature of the media. NBR, EPDM, FKM (Viton), and PTFE (Teflon) are common options. Refer to select the right seal material for your solenoid valve for quick reference on chemical resistance of seal materials.

- De-energized state: Determine if the application needs a normally open, normally closed, or bi-stable valve function.

- Circuit function: Determine whether the application requires a 2 or 3-way solenoid valve.

- Pressure: The valve must be able to withstand the maximum pressure required for the application. It is equally important to note the minimum pressure as a high-pressure differential can cause the valve to fail.

- Temperature: Ensure that the valve materials can withstand the minimum and maximum temperature requirements of the application. Temperature consideration is also essential to determine valve capacity as it affects the viscosity and flow of the fluid.

- Response time: The response time of a valve is the time needed for a valve to go from the open to the closed position or vice versa. Small direct-acting solenoid valves react much quicker than semi-direct or indirect-acting valves.

- Approvals: Ensure that the valve is appropriately certified depending upon the application.

- Degree of protection: Ensure the valve has the appropriate IP rating for protection from dust, liquid, moisture and contact.

Solenoid valves for pneumatics and hydraulics

Solenoid valves can also be used for pneumatic and hydraulic applications, but have a different working principle. For pneumatics, they are commonly 3/2-way, 5/2-way, or 5/3-way valves. For hydraulics, they are commonly 4/2-way or 4/3-way.

- A 3-way pneumatic solenoid valve has three ports: one for inlet, one for outlet, and one for exhaust. They are commonly used to control a single-action pneumatic cylinder, driving pneumatic actuators, and vacuum applications. The valve is used to fill the cylinder and then exhaust it afterwards so that a new working stroke can occur. Therefore, venting is required. Read more about 3/2-way pneumatic solenoid valves.

- A 4-way pneumatic or hydraulic solenoid valve has four ports: two for inlet and two for outlet. This allows the valve to control the flow direction in a pneumatic or hydraulic system, making it ideal for actuating double-acting cylinders or pneumatic actuators. When the solenoid is energized or de-energized, it shifts the valve's position, changing the path of the air or fluid to either extend or retract a cylinder, for instance. Due to their ability to control the movement in two directions, 4-way solenoid valves are commonly used in various industrial applications, including manufacturing automation, where precise control of actuator positioning is required. Read more about 4-way hydraulic solenoid valves and 4-way pneumatic solenoid valves.

- A 5-way pneumatic solenoid valve has five ports: two for inlet, two for outlet, and one exhaust port. The addition of the exhaust port allows the valve to not only control the direction of flow but also to exhaust the air from the system. This is particularly useful in pneumatic applications where rapid movement of cylinders is required, as the exhaust port can quickly release air to allow for faster actuation. 5-way solenoid valves are often used in more complex control systems where precise motion control and speed are essential, such as in robotics, packaging machinery, and material handling systems. The ability to exhaust air directly at the valve can lead to improved system responsiveness and efficiency. Read more about 5-way pneumatic solenoid valves.

Other solenoid valve applications

Common domestic and industrial solenoid valve applications include:

- Refrigeration systems use solenoid valves to reverse the flow of refrigerants. This helps in cooling during summer and heating during winter.

- Irrigation systems use solenoid valves with automatic control.

- Dishwashers and washing machines use solenoid valves to control the flow of water.

- Air conditioning systems use solenoid valves to control air pressure.

- Solenoid valves are used in automatic locking systems for door locks.

- Medical and dental equipment use solenoid valves to control the flow, direction, and pressure of the fluid.

- Water tanks use solenoid valves to control the inflow or outflow of water, often in combination with a float switch.

- Car washes to control the water and soap flow.

- Industrial cleaning equipment

FAQs

What is a solenoid valve used for?

A solenoid valve is used to open, close, mix, or divert media in an application. They are used in a wide variety of applications from dish washers, cars, and irrigation.

How can you tell if your solenoid is bad?

If the solenoid valve fails to open or close, is partially open, makes a humming noise or has a burned-out coil, you need to troubleshoot the valve solenoids. For more information, refer to the troubleshooting guide.

How do I choose a solenoid valve?

Depending upon the media and flow requirement, choose the material, orifice size, temperature, pressure, voltage, response time and certification required for your application.

What is a solenoid?

A solenoid is an electric coil that is wrapped around a ferromagnetic substance (such as iron) that acts as an electromagnet when the current is passed through it.

How does a solenoid work?

When the electric current is passed through the coil, an electromagnetic field is created. This electromagnetic field causes the plunger to move up or down. This mechanism is used by solenoid valves to open or close the valve.